Profiles for soldering reflow of HFC-4S

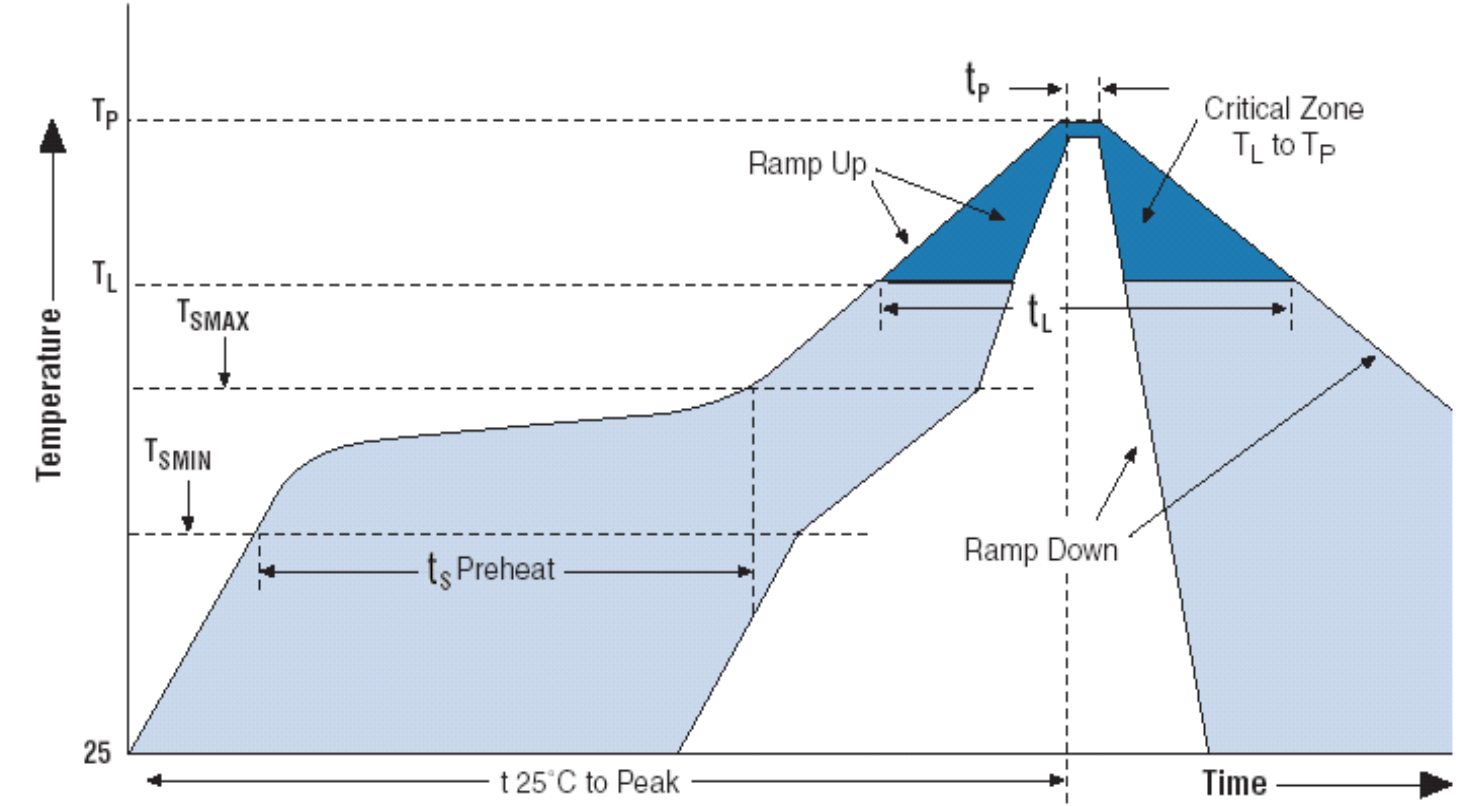

The recommended profiles for soldering reflow of HFC-4S / HFC-8S for Pb-free assembly as well as Sn-Pb eutectic mainly correspond to the commonly applied JEDEC Standard JSTD-020C. To ensure best surface mounting quality, it is recommended to use the provisions of Pb-free assembly. The soldering profile graph (1.) and table (2.) underneath illustrate the respective soldering reflow.

Surface mount products may have a crack when thermal stress is applied during surface mount assembly if they have absorbed atmospheric moisture. It is recommended that these products are handled under specific conditions.

These conditions are described in the following handling recommendations in table (3.).

Profile for Soldering Reflow

Details Soldering Reflow Profile

| Profile Feature |

Pb-free assembly | Sn-Pb eutectic assembly |

| Average ramp-up rate (TL to TP) | 3°C/second max. | 3°C/second max. |

| Preheat - Temperature Min (TSMIN) - Temperature Max (TSMAX) - Time (min to max) (tS) |

150°Cc 200°Cc 60-180 secondsc |

100°Cc 150°Cc 60-120 secondsc |

| TSMAX to TL – Ramp-up Rate |

3°C/second max | |

| Time maintained above: - Temperature (TL) - Time (tL) |

217°Cc 60-150 secondsc |

183°Cc 60-150 seconds |

| Peak Temperature (TP) | 245 +0/-5°C | 225 +0/-5°C |

| Time within 5°C of actual Peak Temperature (tP) | 20-40 seconds | 10-30 seconds |

| Ramp-down Rate | 6°C/second max. | 6°C/second max. |

| Time 25°C to Peak Temperature | 8 minutes max. | 6 minutes max. |

Handling recommendations

| Package Type |

Storage Condition

after unpacking

as maximum

|

Rebake Condition

as minimum

|

| MPQFP 208 (Pb-free) |

Within 168 hours

(30 °C/60% RH)

MSL 3

|

125 °C

24 hours

|